Replace each of the o-rings on the cylinder.Īdd a thin layer of grease to the new o-rings. This way you will be able to match the old o-rings with the new ones, streamlining the overhaul process. It helps to lay out all the o-rings from the kit before you begin replacing them. Remove the piston and bumper from the cylinder assembly. Remove the cylinder alignment ring from the inside of the gun. Now you can remove the cylinder assembly from the gun. This should shake the cylinder loose so you can remove it.ĭo not hit the cylinder assembly with the hammer as you could damage it. Use a rubber mallet or hammer to tap the nail gun housing. Remove the four fasteners that secure the nose piece. Remove the two fasteners and bolt that hold the magazine on the nail gun. Remove the four fasteners that secure the head of the nail gun. This may make them difficult to remove and is normal. Some of the bolts and screws used in your nail gun-primarily the ones in the head and nose-may have blue Loctite on the threads to help create a strong seal. Overhauls in other brands of nail guns will follow similar steps.īefore beginning this repair, be sure you find the right overhaul kit for your nail gun by using our Porter Cable parts search feature.

#PORTER CABLE FN250A REBUILD INSTALL#

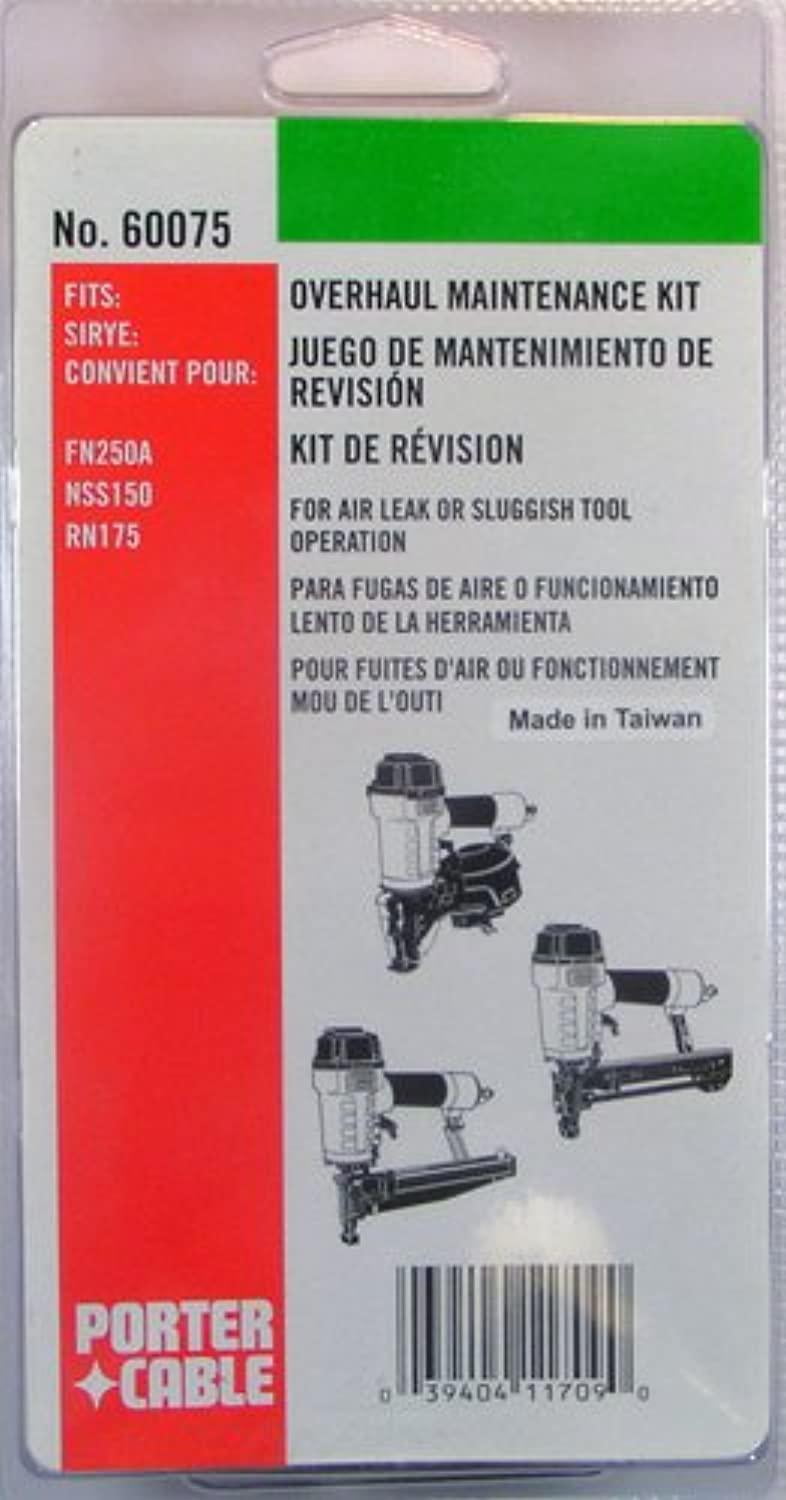

If your nail gun is not leaking air, but has a broken driver, you will want to install a driver maintenance kit rather than an overhaul kit.įor this repair, we used a Porter Cable nail gun. You will need to install an overhaul kit in your nail gun if it is leaking from the nose, head or trigger. These forces can wear down the o-rings in the gun, causing them to leak air. This is because the internal components experience rapid movement, lots of pressure and high forces.

Nail guns require more frequent maintenance than other power tools.

0 kommentar(er)

0 kommentar(er)